Shaping the future.

Now.

We develop plastic solutions for more real climate protection. Every day.

We Are Creator of the Future.

Plastic is the material of the future if it is handled correctly. In these short films, some of our creators of the future report on how they are driving forward the circular economy and resource conservation in their projects. Apprentices also tell us what is important at Pöppelmann – and why they sometimes feel like recycling stars.

Shaping the future.

Since 1949.

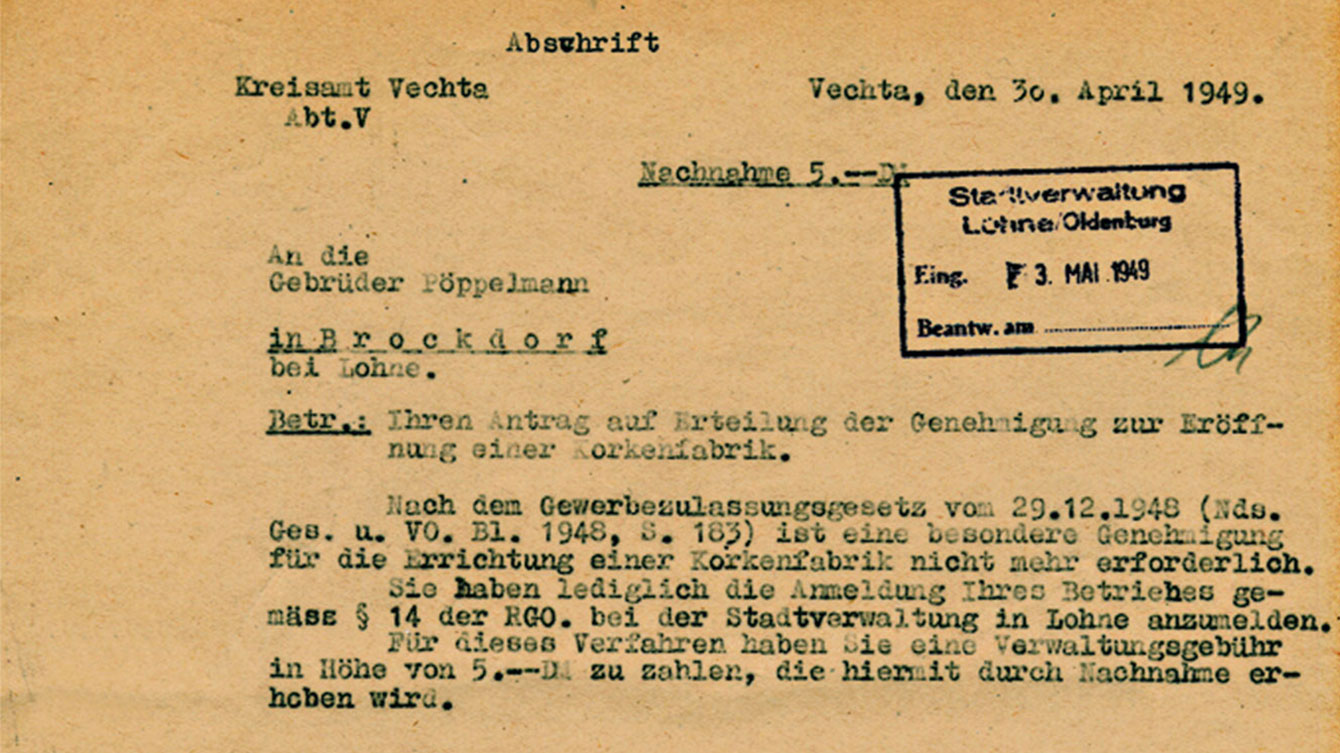

Application for approval of a cork factory.

Submitted to the city council of Lohne by Hubert (22) and Josef Pöppelmann (21). Approved after payment of an administrative fee of 5 German Marks.

The Pöppelmann brothers open their cork factory.

The factory: an old hen house on their parents' farm in Brockdorf near Lohne.

Relocation to Bakumer Straße 2.

Construction of a combined factory, storage and residential building – the nucleus of today’s Pöppelmann Group. Nowadays, the building is home to Lohne’s youth club.

Children,

dare to try something new.

Marriage Josef Pöppelmann & Gertrud Hövemann.

Wedding: Josef Pöppelmann marries Gertrud Hövemann. Even before the wedding, she was active in the company and supported her husband in all business activities right from the beginning. The couple will have six children.

The first plastic product: a grip cap.

Purchase of the first plastic injection moulding machine at Hannover Messe. It is used to make the first grip cap for a cork to close a bottle of spirits. Dawn of the plastics era at Pöppelmann.

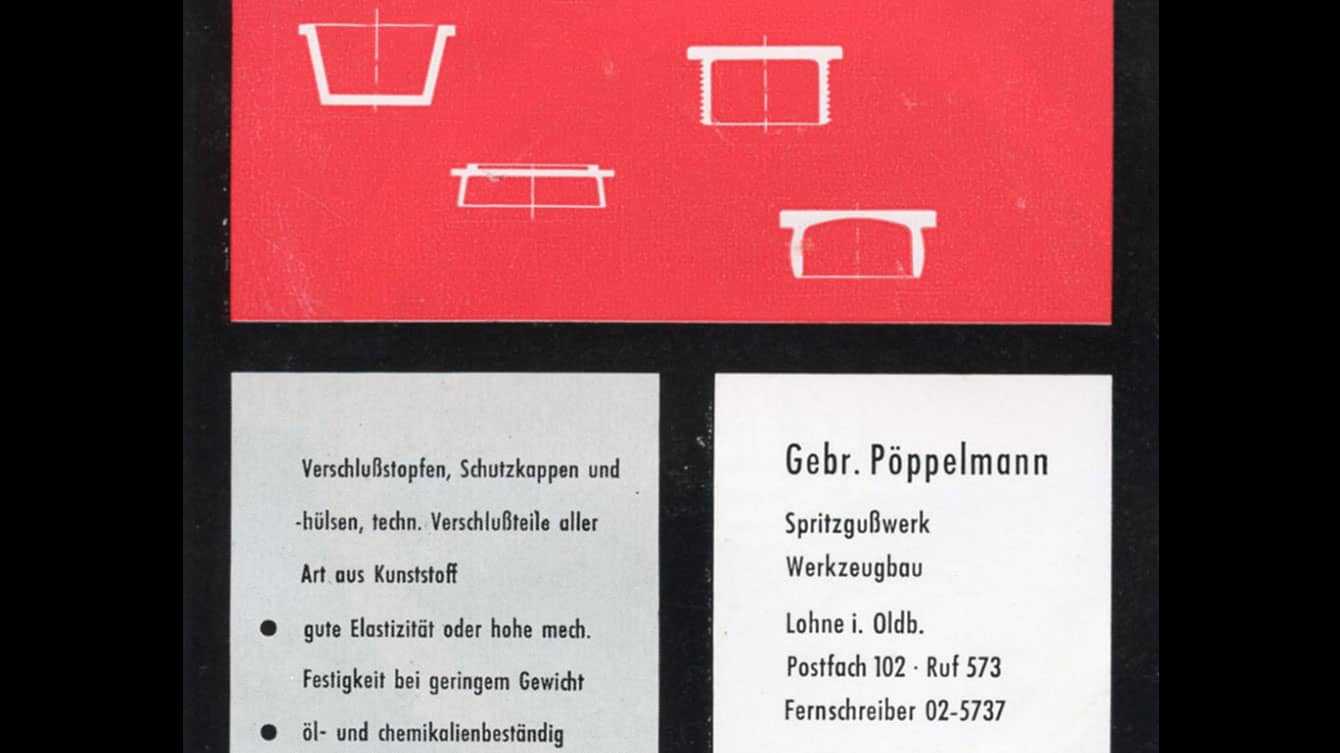

Beginning of KAPSTO®.

Purchase of the first Robling-type mould machine. Very fast development of KAPSTO® sealing plugs and protective caps, as well as protective sleeves, into a versatile range sold across Europe. Use in practically all areas of industry. Still a very popular brand today – even for tailored special solutions.

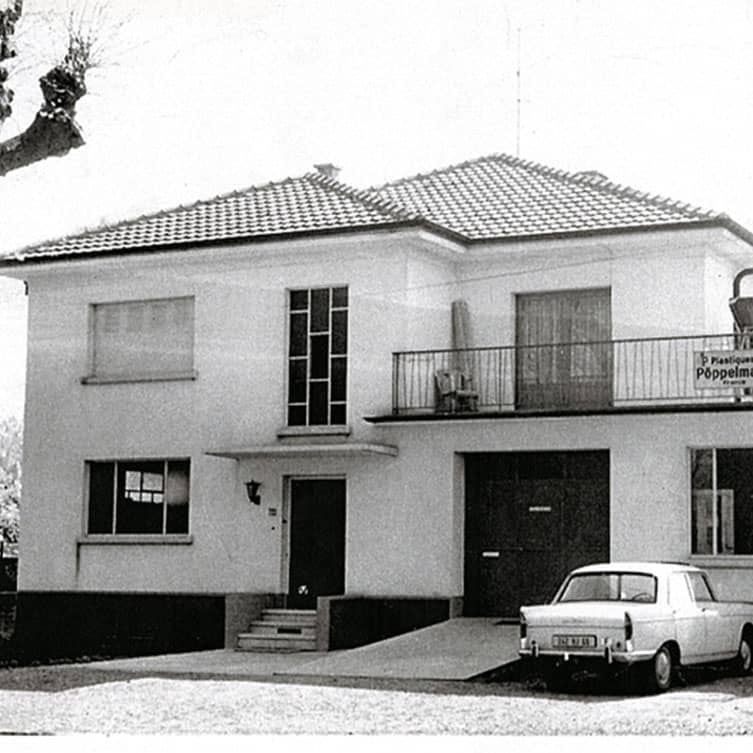

New factory site at Bakumer Straße 73.

Pöppelmann grows. Construction of Hall 1 begins in 1966 on a property on Bakumer Straße. A new administration building is also completed here in 1972 (photo). Further halls and a second office building are added at this location (Plant 1) in the following years.

I am very proud

of our team in Rixheim

Plastiques Pöppelmann France (PPF).

Establishment of the first foreign branch in Rue du Rhin, Mulhouse. Plastiques Pöppelmann France, a free-standing, commercial company, assumes responsibility for the sale of the entire Pöppelmann range in France. Relocation to its own plastics factory in Rixheim in 1977.

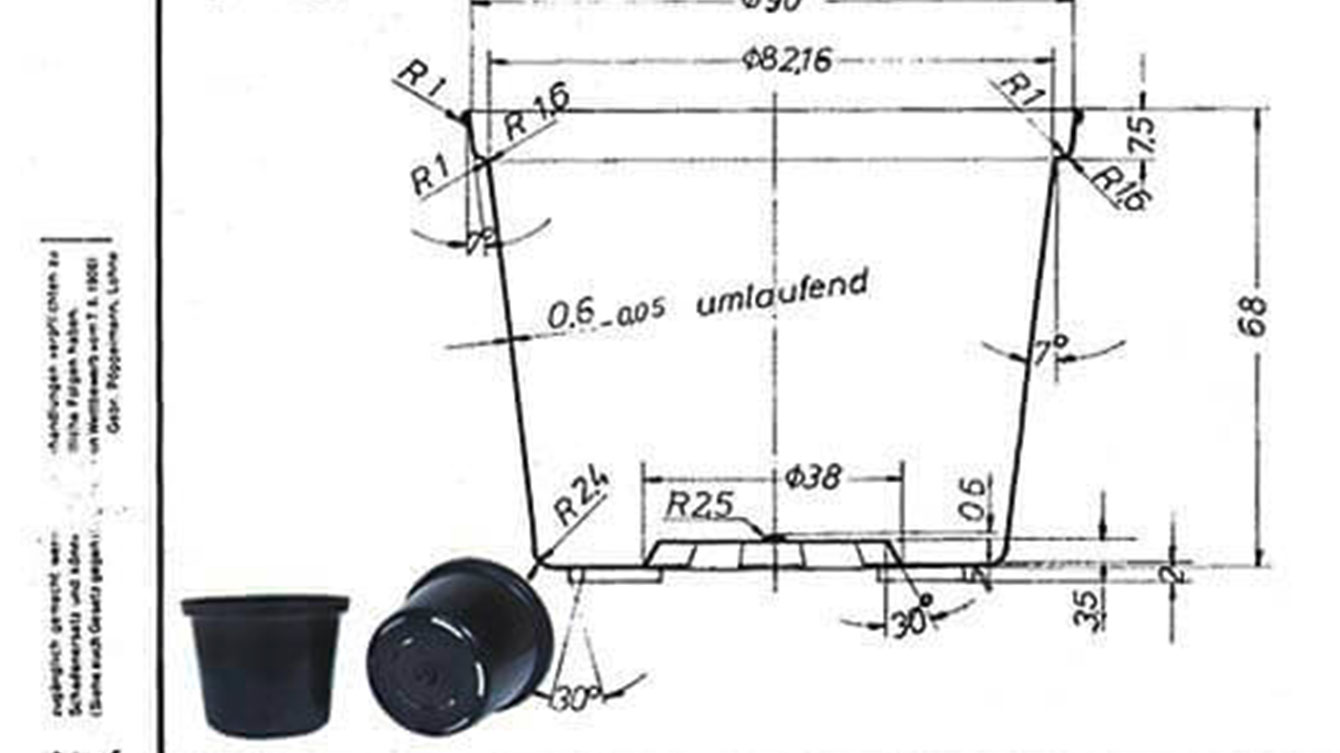

Launch of the TEKU® programme.

The TEKU® program starts with production of the first flower pots. To this day, this business unit develops and produces planters and cultivation systems for commercial horticulture.

25-year company anniversary.

Honouring the pioneers of the company (from right): Aloys Wienhold, Gottfried Thobe and August Böckmann. Simultaneous inauguration of the new premises: Hall 3. The company now has 200 employees. First anniversary brochure entitled “A company introduces itself”. In the following years, Pöppelmann continues to expand.

Josef Pöppelmann dies at the early age of 55.

The company is now managed by Gertrud Pöppelmann and her brother-in-law Karl-Heinz Diekmann. His work is inextricably linked to the company's success story: in 1955, Josef Pöppelmann brought the then 23-year-old into the company as a commercial employee. Just two years later, Karl-Heinz Diekmann became an authorized signatory, and in 1980 Managing Director.

After 47 years, Pöppelmann returns

to the place where it was founded in Brockdorf.

Opening of plant 2 in Brockdorf.

Pöppelmann is growing – and builds its second site in the immediate area of the former Pöppelmann farm in Lohne. The K-TECH division produces high-precision technical plastic components here in Brockdorf under the management of Franz Nordlohne (Managing Director from January 2005)

Change of management.

Gertrud Pöppelmann and Karl-Heinz Diekmann join the Advisory Board and hand over the management of the company to Friedrich Kühling, Guido Schmidt and Alfons Sieverding (from left).

The company celebrates its 50th anniversary.

With 800 employees and subsidiaries and branches in France, Spain, UK, Denmark, Belgium and the Netherlands, Pöppelmann is one of the leading companies in the plastics processing industry in Europe. The commemorative publication “The first fifty years” [1949 – 1999] is released.

Pöppelmann Plastics USA (PPUSA).

Site opening with the TEKU® division in Claremont, North Carolina. The Pöppelmann group employs more than 1,300 people worldwide.

Stick together

and respect each other.

Company owner Gertrud Pöppelmann dies at the age of 84.

The group of companies remains 100 percent family-owned. Friedrich Kühling, Norbert Nobbe and Franz Nordlohne manage the company.

Trip to Rome

On the occasion of the company's 60th anniversary, the motto is: “Off to Rome!” At the invitation of the Pöppelmann family, employees and their partners experience unforgettable days in the Italian capital.

Inauguration of Factory 3.

Pöppelmann FAMAC® develops and produces sophisticated plastic functional parts and packaging for the medical, pharmaceutical and cosmetics industry.

Holdorf compounding plant starts operations.

In order to reduce the consumption of fossil fuels, Pöppelmann produces high-quality recyclates from plastic waste.

We take

responsibility.

Foundation of the PÖPPELMANN blue® initiative.

With PÖPPELMANN blue®, the company has set itself strategic targets for climate protection and resource conservation throughout the organisation.

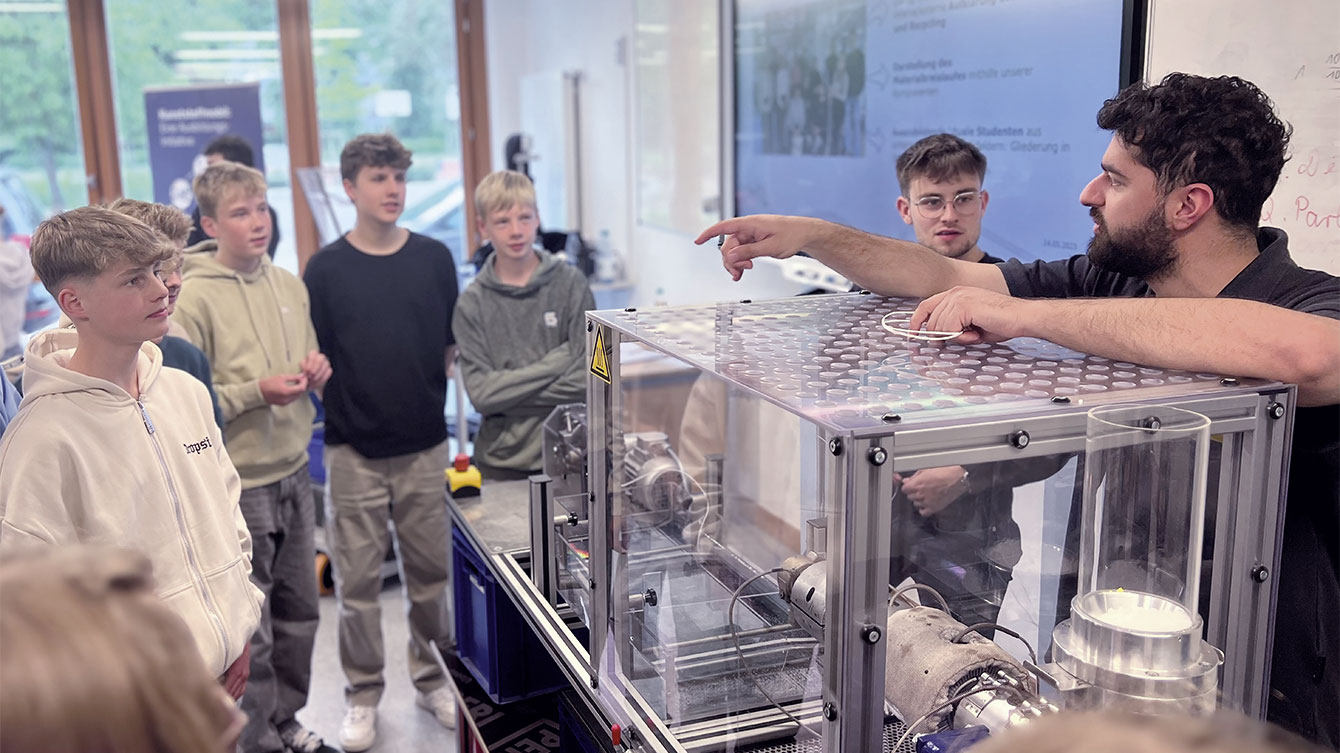

Expansion of the learning workshop into a training centre.

In hall 26 in plant 2, trainees and apprentices in technical professions are instructed at state-of-the-art training centres in the fields of plastics technology, technical communication, electrical engineering and metal technology.

The third generation continues the family tradition.

The third generation of the family is responsible as shareholders (from left): Maximilian Forst (member of the Advisory Board), Felicitas Pöppelmann, Catherin Vitale (Chairwoman of the Advisory Board) and Vincent Otto.

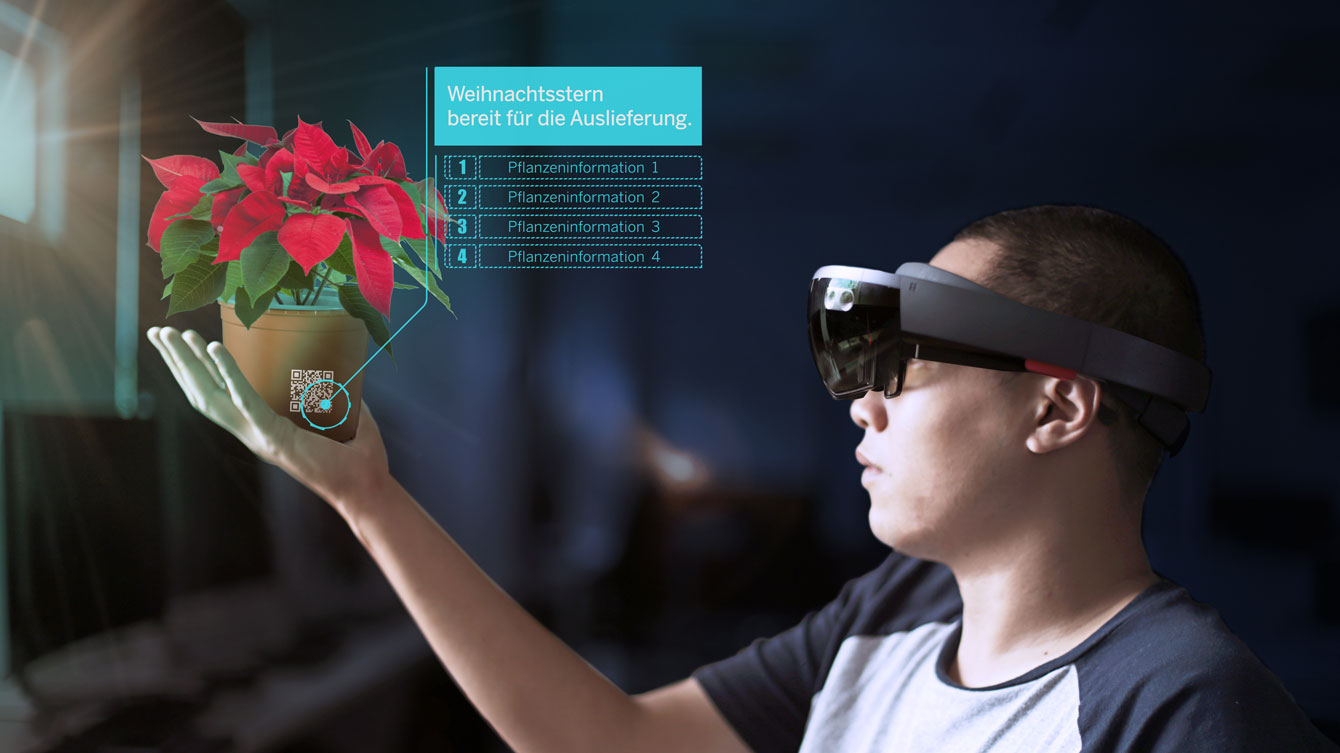

Foundation of the PPdigital corporate initiative.

Pöppelmann combines experience and expertise across the company to actively shape the digital transformation and establish new services on the market.

Our strong US team

opens up many new opportunities for us.

US plant expands capacities.

Start of construction of hall 3 at the US Pöppelmann plant in Claremont, North Carolina.

Start of construction of hall 43.

Plant 2 is one of the most modern plastics processing sites in Europe. The planning and realisation of the new hall follows the standards of the German Sustainable Building Council (DGNB).

Honoured as a climate protection company.

Federal Environment Minister Steffi Lemke admits Pöppelmann to the Klimaschutz-Unternehmen e. V. association. This is a network of German companies that are actively committed to climate protection, energy efficiency and the sensible use of resources. The initiators are the Federal Ministry of Economics, the Federal Ministry for the Environment and the German Chamber of Commerce and Industry.

Opening of the technology centre.

New materials and innovative production technologies are designed and tested in the new technology forge in plant 2.

Commitment and team spirit

secure our future.

“Science Based Targets initiative” confirms Pöppelmann's 2030 climate targets.

The SBTi is a joint initiative of the global non-profit environmental organisation CDP, the United Nations Global Compact, the World Resources Institute (WRI) and the World Wide Fund for Nature (WWF). It has reviewed the company's climate targets and confirmed that they are in line with the 1.5 degree target of the Paris Climate Agreement.

Opening of the Digital Lab.

New technologies can be experienced in the Digital Lab. The close proximity to the training centre is fitting – since the Digital Lab is also about learning and understanding how the digital transformation has changed and will continue to change the work at Pöppelmann. All colleagues are invited to familiarise themselves with digital technologies in this unique learning workshop.

“Zukunftsmobil” Initiative.

They are shaping the world of tomorrow: in this initiative, since 2018 apprentices from different years and various training professions are making the topics of plastics, material cycles and recycling “mobile” in a very practical way. They are also happy to provide information about them as a “mobile workshop” in schools and at events.

Pöppelmann – a strong partner.

With six production sites at its headquarters in Lohne (Germany), Rixheim (France), Claremont (North Carolina) and Kunshan (China), the family-owned company Pöppelmann is one of the leading plastics processors in the industry. More than 2,500 employees worldwide produce innovative plastic products for global markets, including the automotive, medical technology, food, cosmetics and pharmaceutical industries as well as horticulture.

The Pöppelmann

family.

Josef Pöppelmann

At the age of 21, Josef Pöppelmann (1928 – 1983) founded a cork factory together with his brother – in a chicken coop. He was an entrepreneurial personality who steered the company on a sustainable path to success with drive, a flair for change and courage. His enthusiasm set a unique company history in motion in 1949 and remained a driving force even after his early death. A doer who shaped the future.

Gertrud Pöppelmann

She was a modern woman, deeply rooted in faith and nature. As an adolescent, Gertrud Pöppelmann (1924 – 2009) completed her commercial apprenticeship with distinction, unaware that she would one day be the head of one of the largest companies in the region. She treated her “much-loved Pöppelwomen and Pöppelmen” with modesty, gratitude and respect. Her humanity and kindness perfectly complemented the skills of the managing directors next to her, moulded the workforce – and continue to have an impact on the corporate culture to this day.

The third generation.

Maximilian Forst (Advisory Board member), Felicitas Pöppelmann, Catherin Vitale (Advisory Board Chairwoman) and Vincent Otto are currently responsible as shareholders (from left to right). Their ambition: to actively shape the future with commitment and creativity. Their goal: to inspire the world of tomorrow with future-proof, innovative and sustainable products. To achieve this, they rely on commitment, team spirit and an honest and open corporate culture.